| |

|

|

Engineering /

“O”-RINGS

“O”-RINGS

When

choosing an “O”-ring there are several factors to

consider in determining proper selection including:

the application for which the “O”-ring is to be

used; the media to be sealed; the size of the

fastener to be sealed; and the temperature and

pressure to which the “O” ring will be subjected.

Once each of these factors has been considered and

an “O” ring has been chosen, engineering

calculations should either be checked manually or

by using “O” ring selection software.

Materials

Our

customers can choose from six basic materials which

come in durometer ranges from 60-70 hardness

depending on the chosen material. In addition to

the materials listed below, other materials are

available upon request.

|

|

|

Temperature

Range Chart

(Click to Enlarge) |

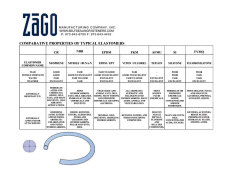

Comparative

Properties

of Typical Elastomers

(Click to Enlarge) |

-

ETHYLENE PROPYLENE (EPDM)

Our

EPDM compounds are commonly used in outdoor

environments and are excellent for weather &

water resistant applications/appliances having

excellent ozone, steam and chemical resistance.

The standard temperature range for EPDM ranges from –54°C

to 107°C and –65°F to 225°F.

Other temperature ranges available upon request.

-

BUNA- N (Nitrile)

Our

Buna-N compound is the most common seal material

chosen by our customers because of its versatile

resistance to petroleum-based substances, water and alcohols.

The standard temperature range for Buna-N is

from –40°C to 107°C and

-40°F to 225°F.

Other temperature ranges available upon request.

-

NEOPRENE (Chloroprene)

Our

neoprene compounds are commonly used in the

refrigeration industry for their resistance to

ammonia and freon. Neoprene is also used for

numerous applications in the automotive industry

because of its excellent resistance to oil.

Resistance to ozone, sunlight and oxygen also

make this a great choice for products exposed to

adverse weather conditions. The standard

temperature range for neoprene ranges from -40°C

to 107°C and –40°F to 225°F.

Other temperature ranges available upon request.

-

SILICONE

Our

silicone rubber has an excellent temperature

range and can withstand low temperatures without

becoming brittle. However, it is usually

not recommended for dynamic seals because it

does not have optimal solvent or oil resistance.

The standard temperature range for silicone is

from -62°C

to 204°C and -80°F to 400°F.

Other temperature ranges available upon request.

-

FLUOROSILICONE

Our

fluorosilicone compounds are commonly used in

the automotive and aerospace industries because

of their excellent fuel, oil and solvent

resistance. The standard temperature range for fluorosilicone is from –55°C to 177°C and

–67°F to 350°F.

Other temperature ranges available upon request.

-

FLUOROCARBON (VITON)

Our

Viton compounds are the preferred choice when

seals are required for aircraft engines and

automotive fuel handling because of its

excellent resistance to high temperatures and

harsh chemicals. The standard temperature range for Viton is from –29°C TO 204°C and –20°F

to 400°F.

Other temperature ranges available upon request.

Any

application of an elastomer in an environment with

temperatures near its extreme cold or hot limit

should be tested to assure performance.

MILSPEC “O” RINGS

ZāGO

Manufacturing offers military standard “O”-Rings

which meet the following military specs:

-

General Purpose Buna N

-

Buna

N - Mil P 5315

-

Buna

N – Mil P 25732

-

Buna

N – Mil R 6855

-

Ethylene Propylene

-

Fluorosilicone – Mil R 25988 TY 1 CL 1

-

Silicone – ZZR 765 CL 2A or 2B

-

Fluorocarbon (Viton) – MIL R 83248 CL 1

-

Brown Viton

-

Neoprene

-

Teflon AMS 3652

FDA-Approved

“O” Rings

ZāGO can

provide the following FDA approved “O” Rings:

-

BUNA

-

EP

-

SILICONE

-

VITON

CUSTOMER TESTIMONIALS

|

|