|

Engineering /

Installation and Torque

Installation

and Torque

With

respect to installation and torque, there

are three important design calculations and they are

as follows:

-

Percent Squeeze – giving standard torque

installation (see Table)

-

Compression/Stretch percent

-

Groove Volume

Since

there are wide ranges of sealing applications, more

calculations may be required. If you are using

standard sealing applications, then the calculations

have already been done: (See tables 2 & 3)

On the

other hand, if the application is unique, then these

calculations will need to be tabulated.

IMPORTANT: Calculations must be as accurate as

possible to avoid an end result of leakage.

|

NOMINAL

SCREW SIZE |

INSTALLATION

TORQUE (in. – lbs.) |

|

(#4) |

.112 - 40 UNC – 2A |

|

(#6) |

.138 - 32 UNC – 2A |

|

(#8) |

.164 - 32 UNC – 2A |

|

(#10) |

.190 - 32 UNF – 2A |

|

(#10) |

.190 - 24 UNC – 2A |

|

(#1/4) |

.250 - 20 UNC – 2A |

|

(#5/16) |

.312 – 18 UNC – 2A |

|

(#3/8) |

.375 – 16 UNC – 2A |

|

5

9

20

23

23

75

142

263 |

NOTE:

THE ABOVE VALUES ARE RECOMMENDED AVERAGE VALUES

ONLY. VARIATIONS IN MATERIAL AND LOCAL CONDITIONS

MAY REQUIRE SIGNIFICANT DEVIATIONS FROM THE

RECOMMENDED VALUES.

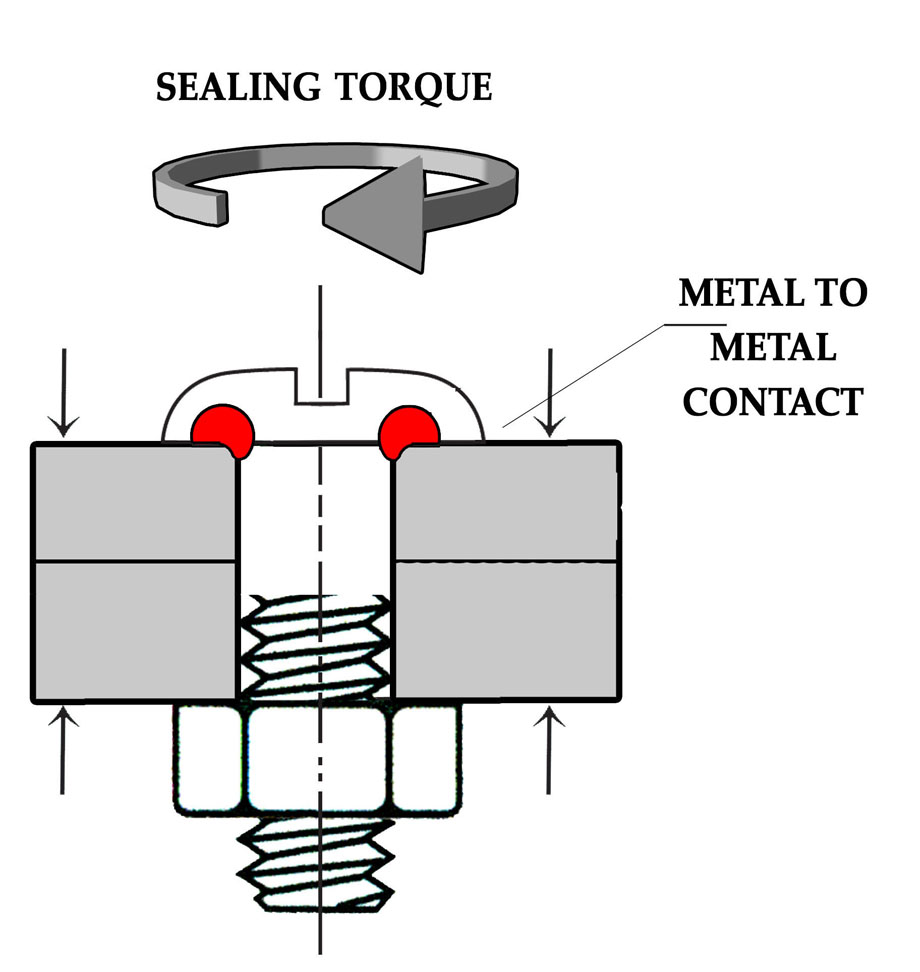

Sealing Torque

(Click to Enlarge)

CUSTOMER TESTIMONIALS

|